Nucleon is a professional crane manufacturer and material handling solution provider.

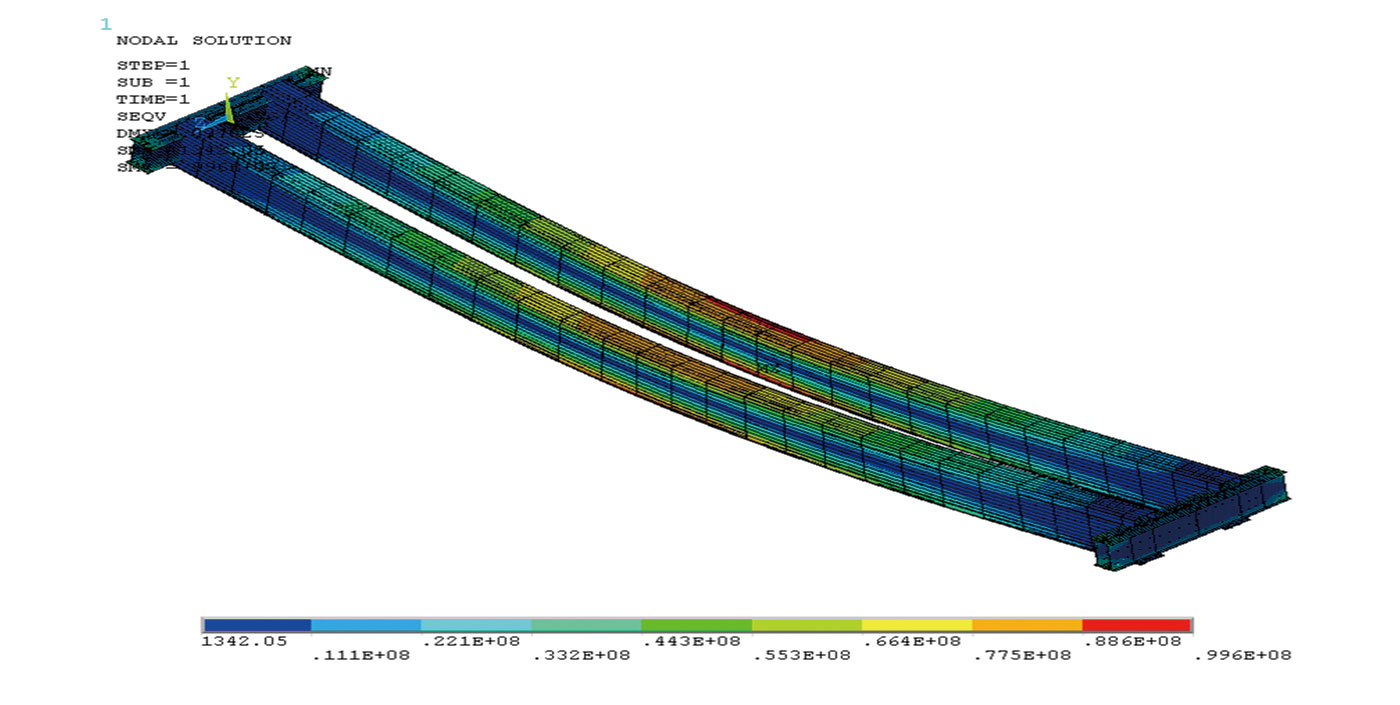

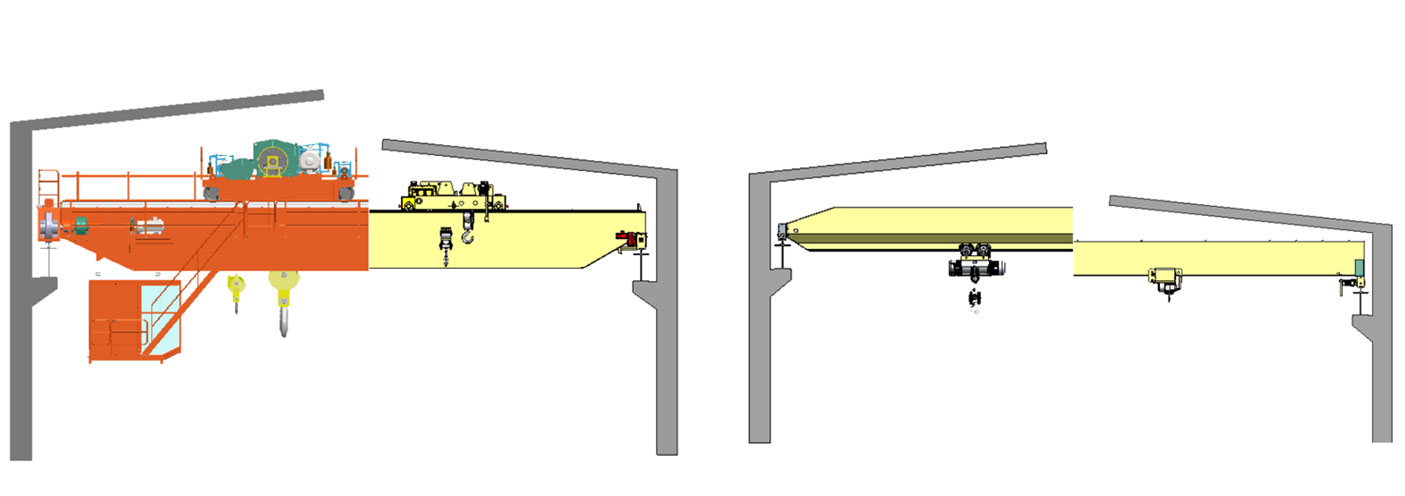

一、Lightweight trolley design Lifting mechanism: ◆ High-efficiency variable frequency motor ◆ Hard tooth surface reducer ◆ High-strength reel set ◆ High-strength galvanized steel wire rope ◆ Rolled or high-strength nylon pulley block ◆ High-strength hook set Trolley frame: H-shaped three-beam structure composed of one horizontal beam and two longitudinal beams. The whole crane adopts modular design and compact layout. | 二、Lightweight design of traveling mechanism ◆ High-efficiency variable frequency motor ◆ Hard-toothed mute reducer ◆ High-strength wheel set ◆ Machined boring holes are used to improve the installation accuracy of the wheel set ◆ Both single wheel structure and boogie structure to meet different wheel pressure requirements | 三、Lightweight structure design ◆ High-strength square steel rails instead of P-type rails, and the fixing method is changed from pressing clips to welding clips. ◆ The bridge frame adopts a box-type four-beam structure, and the main beam and the end carriage beam are connected by high-strength bolts, which are convenient for processing, transportation and installation. ◆ The objective function optimization method is used to optimize the design of the steel structure of the crane, and the size of the steel structure is reduced under the premise of satisfying the stiffness and strength. |

The new design crane reduces its height by 30%, weight by 25%, and comprehensive energy consumption by 20%;

Higher effective lifting height, lower plant height.

TikTok QR Code

TikTok QR Code

WeChat QR Code

WeChat QR Code

Homepage QR Code

Homepage QR Code

Tel:+860373-8622016

Fax:0373-8622001

Email: nucleon@nucleon.com.cn

Address:crane indusry park, Changyuan City, Henan Province, China